Pam and I had gone to the local pizza place for some takeout. In typical “I’ll buy, you fly” mode, Pam drove the F-150 with me in the passenger seat. She parked head-on by the front door and waited while I ran in for the goods.

It was just past closing time. Staffers killed the lights and ran out the door behind me.

Pam selected reverse and backed out, then pulled the lever for drive, hit the gas – AND THE TRUCK SURGED BACKWARD!

There wasn’t much room in the lot so she maneuvered to the curb, occupying about three marked spaces, and killed the engine.

It’s dark, beginning to rain, maybe three or so miles from home, hot food in the back seat, and we’re hungry. I called the kid for a lift home. We’d eat and think, then come back. Maybe the rain would pass.

The console lever felt sloppy, disconnected, I suspected a mechanical issue like a linkage or cable had worked its way loose. The console lever has a history. I removed the plastic shroud and felt around as best I could in the darkened cab; nothing felt out-of-place and my earlier hack/repair felt intact.

The kid soon arrived. We locked up and left to eat.

Sure enough, a bit of Internet searching turned up lots of similar failures! The most common issue came down to the cable-end detaching from the transmission lever. We returned to the truck armed with a good flashlight and I crawled under for a look. Before you ask, yes, the rainwater had pooled underneath…

Now it was clear that the cable-end was no longer attached. By manipulating the console and transmission levers it was possible to reattach, but when the console lever moved the cable end fell right off. The press-fit retention was no longer retaining!

I figured we could get the truck home, though. That’d free up parking for the restaurant and make for more comfortable work. The safety interlock only allow the truck to start in park and I could manipulate the levers to do that from beneath. With the truck started I could move the transmission lever into drive while Pam applied the brake. Then I’d crawl out she could drive home.

Pam was less than thrilled with the idea. But she did it. She probably pressed that brake pedal almost through the floorboard while I was under the truck fiddling with the transmission lever, engine running!

The Root Cause

The cable end is a roundish half-bowl of plastic molded onto the semi-flexible metal rod that extends from its sleeve. In the picture you can see a white plastic insert fitting in the black bowl. The transmission lever has a protruding machined knob that’s captured by that bit of white plastic.

Failure occurs when the white plastic insert no longer captures the knob.

The cable assembly is not adjustable. The length is exactly what it is. That’s important because…

When the console lever’s placed in park – that’s how the truck spends much of its time since being manufactured – there’s much linear force being applied against the transmission lever. By that I mean if you select park and slip the cable end free of the transmission lever (easy to do, now that the part’s failed), the cable end springs out extend a good 3/8″ past the transmission lever. You cannot put it back in place without manipulating the console lever positions, the end-to-knob alignment is that far off. So of course that 29-cent bit of plastic will fail eventually! It’s designed to fail!

The Repair

The cable assembly – part number 4L3Z-7E395-CA for my 2004 unit – is available on Amazon for about $48. I don’t have a shop manual – that’s another story for another time – but it looks like it could be replaced in a couple of hours. Beer optional.

Obviously, a dealership could handle the repair. I heard that runs around $300-$350, including parts.

But let me introduce you to Ascension Engineering. They produce a line of replacements for those little white pieces of plastic – apparently it’s a common failure mode across a wide variety vehicles, not merely Fords. The parts sell through their website, BushingFix.com. And business is apparently pretty damned good – Ascension Engineering’s principal relocated to some considerably nicer digs between May 2015 and March of 2016…

Y’know, $25 is a lot of money for a bitty bit of plastic. (Update: I learned, when sending a link to this article to the manufacturer for review, that the price is now reduced. My luck, right?) Okay, there’s design, tooling costs, manufacturing, but any number of Chinese outfits will do all that. Probably including the engineering design, too. It seems likely that they already manufacture those little bushings for the auto manufacturers. That Mr. Smith, he’s one smart cookie!

Screw it. I ordered a kit. There was sales tax, we’re both in Florida. And shipping was, I thought, a little high at just under $6 for USPS. The total cost was $32.29. I showed up at my door in a few days, shipped from Charlotte, North Carolina.

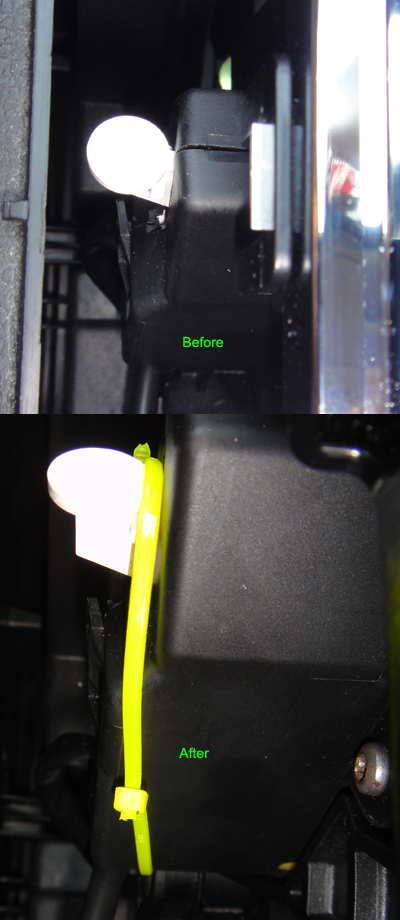

But First, An Interim Hack

A couple of weeks before the order and permanent repair, a simple hack was necessary to keep the truck on the road. A truck’s a useful tool here in rural Florida. There’s trash and recycling to haul, stuff like that.

I hacked up a little cage from (what else?) coat-hang wire – easy to work with, yet stiff enough to enclose the cable end.

It’s got some nifty features. First, it’s a cage. It’s solidly attached to the transmission’s shift lever and doesn’t contact the cable or its end except where it absolutely must, to prevent the thing from slipping off the knob. That contact is minimized by a custom thrust plate constructed of softer plastic. (Don’t be fooled, the thrust plate is from a plastic storage bin. We use the bins as high-walled litter boxes for our feline residents, and this is the material cut out to form a door.) Notice the bend in the thrust plate, and the cutouts so the cage retains it.

The hack would likely outlast the truck. But a replacement part was on the way.

The Replacement Bushing

It arrived in about a week. Here’s what $32.29 bought me:

Three bits of plastic: the bushing itself plus two more that served as press-blocks. Click to enlarge the image and see the instructions. Leaning way towards foolproof, I’ve gotta say. It took me longer to remove my hack than it did to install the replacement.

Part of the install involves digging out any old bushing parts from the cable end cup. I used a carbide-tipped scribe and it cleaned up in a few seconds. Here’s a shot of what was left in my cup before that step. Pretty disgusting. But what’s clear as an unmuddy lake is how the linear force of sitting in Park had basically ruined one side while the other remained basically unworn. Ford’s non-adjustable setup is designed to fail. It’s only a matter of time.

I assembled the sandwich of plastic bits and used a pair of Channellock pliers to give it a squeeze. I chose the Channellocks because of the adjustable jaws but I think a pair of ordinary pliers like those found in the average person’s tool bag would have done the job just as well. You’d need pliers, though, it’s a bit much for fingers alone.

The rejuvenated cable end mated to the transmission lever with a satisfying click. Then I exercised the console lever. It felt great.

Notice in the completed repair image that there’s a slight gap between the cable-end cup and the transmission shift lever. This tells me that the replacement bushing is the proper size for the job. If the knob sat too deep then the two parts would rub, wearing the cable-end cup.

So How’s It Holding Up?

It’s been a few months since all this went down and so far, so good.

No issues, no complaints, the repair feels as tight as ever. How long will it last? Hard to say. Ford’s designed-to-fail assembly of the subsystem remains unchanged. What’s a worse environment? New Jersey winters or the Florida heat? Time will tell.

The other night the Ford F150 left us stranded.

The other night the Ford F150 left us stranded.